Product Description

Auto Trans Kick Down

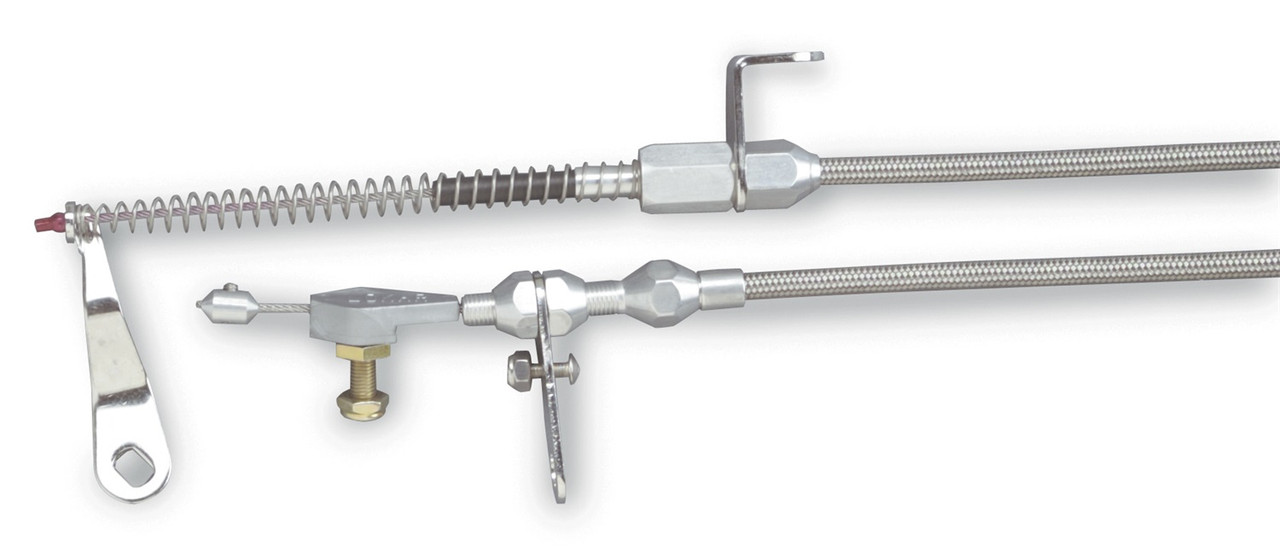

Hi-Tech Kickdown Kit

Hi-Tech Kickdown Kit; U-Cut-To-Fit; Incl. Aluminum Fittings w/Ferrule/Instructions; Black Housing; Stainless Steel Finish;

- Trans Model: Ford- AOD (Auto) 4 Speed

- WARNING CA Proposition 65: Yes

- WARNING CA Proposition 65 Message: WARNING: Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

- U-Cut-To-Fit Design Works In Any Application

- Specially Extruded Liner For Extended Cable Life

- Aluminum Ferrule To Eliminate Fraying

- Made In The U.S.A.

- Lifetime Warranty

Lokars U-Cut-to-Fit Kickdown Cables are available in either stainless steel braided housing, black stainless steel braided housing or black housing. They are designed with a specially extruded liner for extended life of the cable - not to be confused with ordinary brake hose. Kickdown features aluminum fittings with ferrule to eliminate frayed cable ends. Kickdowns are adaptable for all types of manifolds including tunnel ram, blower manifolds and Weber induction systems. Mount our kickdown with our Stainless Steel Carburetor Bracket and Return Springs (sold separately). Complete instructions included in kit. Polished kickdown cables will include polished aluminum fittings. Black Hi-Tech stainless cables will include black anodized aluminum fittings.

Quality.. Plain & Simple...It's that easy. Lokar bases their entire business on the simple ideals of manufacturing a quality product and providing quality service, before and after the sale. We will not compromise that ideal. Our commitment is to provide the automotive aftermarket enthusiast with the best possible products and service. We pride ourselves in the availability, reliability and versatility of all our products. When Lokar began it's operation in 1988, the goals were simply to make a better product than what was available, and to design products which would be simpler to install, more versatile in application and affordable all at the same time. We continue to strive for those goals every day. We have been able to maintain quality control over the years by becoming more self-sufficient in the manufacturing process. Our facility houses nearly all of the manufacturing processes necessary to guarantee our customers a quality product. This includes CNC mills and lathes operated by factory trained machinists, to produce consistent quality aluminum and steel parts; welding and finishing work to guarantee the durability and finish of our products and assemblers and packers who are trained to provide you with the quality we expect. Our entire product line is assembled, packaged and shipped by a full time staff from our location. We are here to assist our customers after the sale too! Our technicians are trained to provide you with information to answer the simplest or most complicated questions, from application to installation to customization. We would like to extend a great big THANK YOU to all of our customers who have been the biggest part of our success and extend an invitation for you to continue your patronage with the promise that we will continue to serve you with.Quality... Plain & Simple.